KIYA Corp. will strive for new solutions to our customer’s needs, over and beyond the framework of metal processing by using our core competence technology, Cold forging progressive press technology.

Technological pattern suggestion❶

Groove molding from metal sheets

Changing from cutting/sintering process to only using one method of stamping process technology for grove molding. We successfully reduced the cutting defects to “Zero” using this technology.

Technological pattern suggestion❷

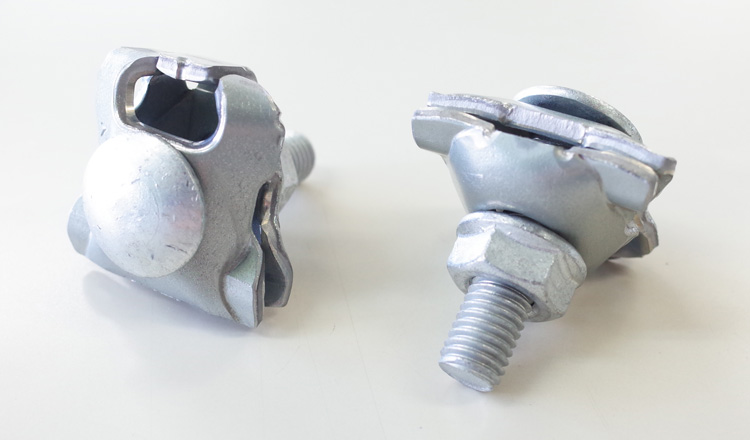

Cylinder shape integral molding formation from metal sheet material.

Technology which needed 2pieces of cylinder shapes to attach can now be formed by integral formation using pipe material stamping process. We can reduce cost dramatically using near net shape method.

Technological pattern suggestion❸

Sheet thickness control processing

This technology can single handedly control the sheet thickness freely for product needs. This technology can maintain higher strength compared to cutting or die casting product due to the fiber flow not being interrupted.

Technological pattern suggestion❹

Capacity to propose from the material structure to production all in one go.

Kiya has the technology and capability for designing, production, surface treatment, using various steel materials and transporting product to the construction site. Expertise and experience in many different environment and locations is also our strength.

Technological pattern suggestion❺

Product development pursuing workability

Technology for developing products which focuses on reduction in tightening points, weight saving and versatility. We develop and deliver safe and optimal products for customers in telecommunications, electricity, infrastructure, public or amusement facilities.

Technological pattern suggestion❻

Hybrid processing in Metal + different material

Kiya is focusing in hybrid processing to combine different metal shapes with different material characteristics such as airtightness, rust prevention, insulation, or elasticity.

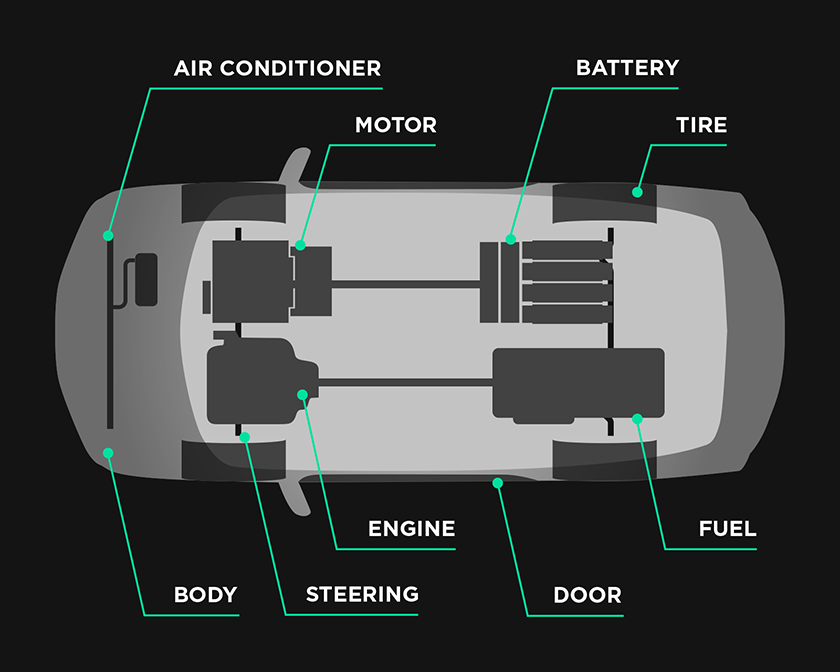

Automotive components

KIYA Corp. not only produce gasoline-fueled automobile but also environmental car (HV、PHV、FCV、EV) parts in different materials and thickness to Tier1 companies both domestic and overseas.

For Future generation automobile technology and markets. KIYA will continue to challenge for future demands.

Heat exchanger related components

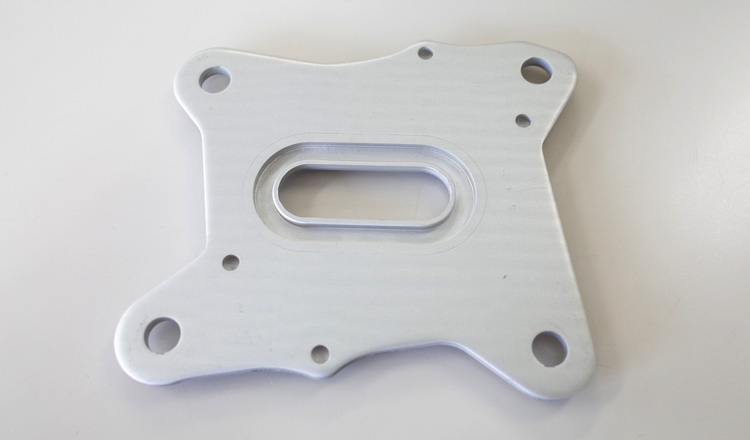

EGR-C Flange component

Formed with a thin wall thickness. We have managed to cut cost by 20% though our developed product without using cutting process.Material:SPHC

Thickness:8.0mm

Cooling water control valve component

Cylindrical shape product. Formation of cylindrical shape with shape at formed on both ends, secured parallel flange surface alignment.Material:SPCE

Thickness:3.2mm

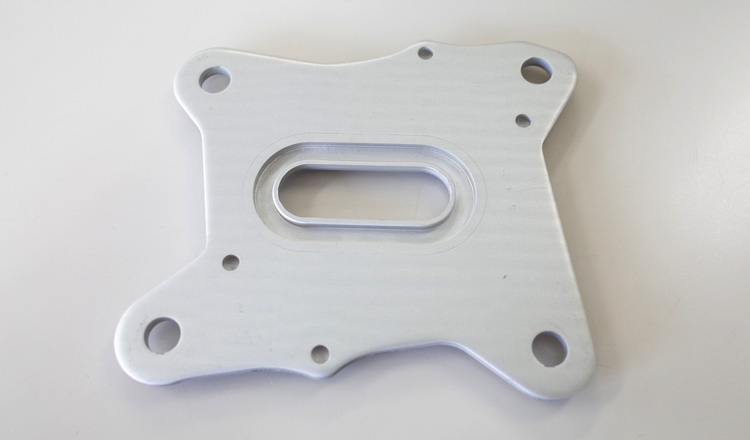

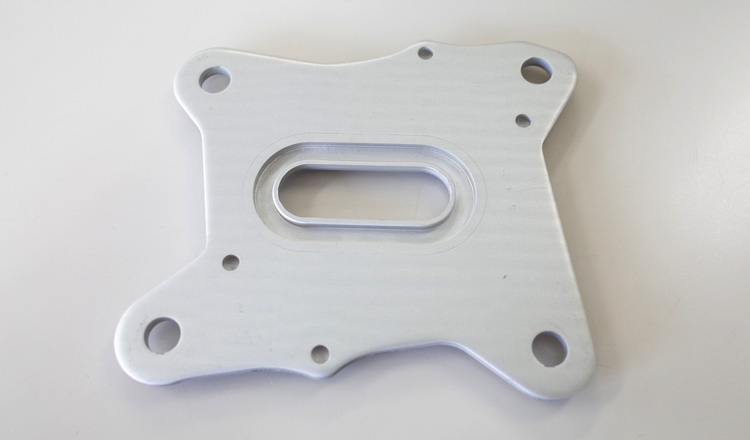

Oil cooler component-1

Long hole shaped burring mold. Radius and straight length cross-section shape difference, minimized.Material:A3003

Thickness:4.5mm

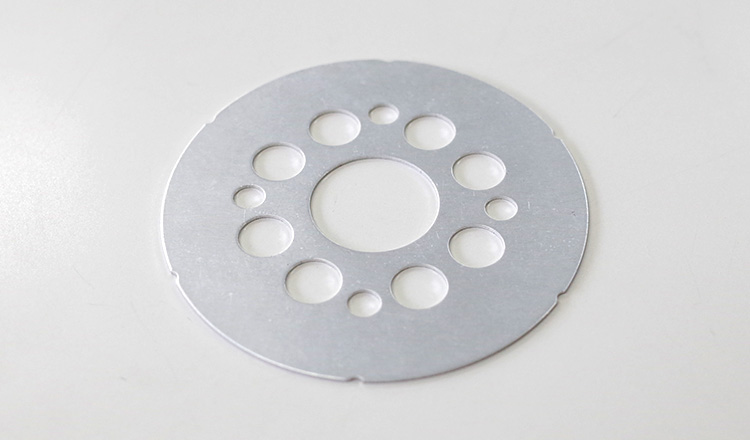

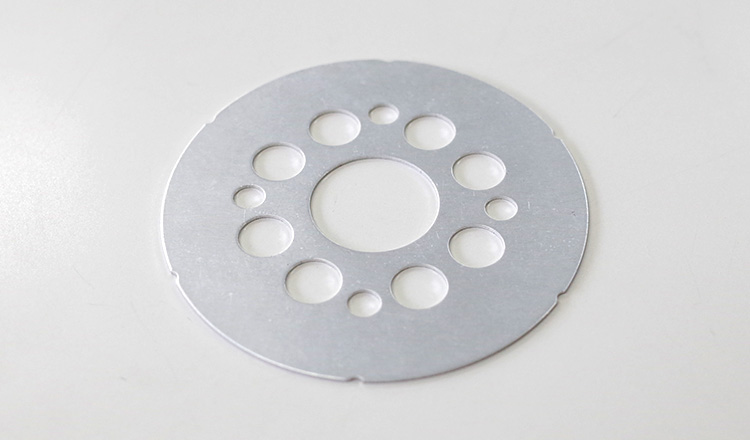

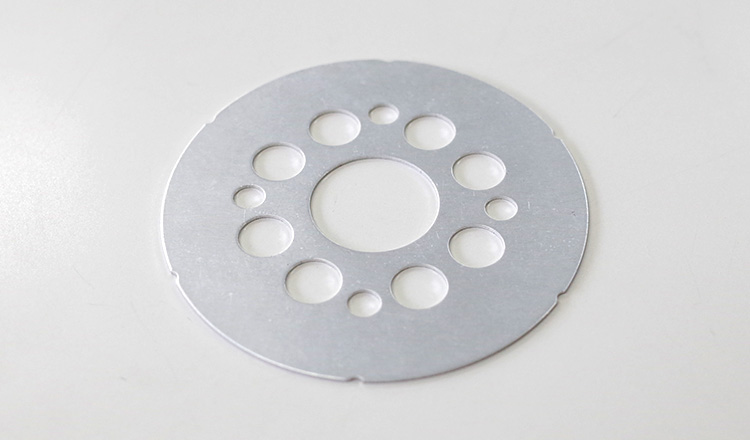

Oil cooler component-2

Large diameter grooved mold. We have changed our manufacturing process from conventional cutting and stamping to a new method of single stamping process.Material:A3003

Thickness:4.5mm

Oil cooler component-3

Drawing diameterφ90~100, internal diameter tolerance of ±0.05 is achieved.Material:SUS304

Thickness:0.8mm

Oil cooler component-4

Material:A3003Thickness:4.5mm

EGR-C component

Stainless steel sheet - precision bending, mold process.Material:SUS430J1L

Thickness:0.8mm,1.0mm

Material:SUS444

Thickness:0.3mm

Pipe component

Integrally molded cylindrical shape and bottom plateMaterial:BAW7-O

Thickness:1.6mm

* Made in Japan

EGR-C Flange component

EGR-C Flange component

Formed with a thin wall thickness. We have managed to cut cost by 20% though our developed product without using cutting process.

Material:SPHC

Thickness:8.0mm

Cooling water control valve component

Cooling water control valve component

Cylindrical shape product. Formation of cylindrical shape with shape at formed on both ends, secured parallel flange surface alignment.

Material:SPCE

Thickness:3.2mm

Oil cooler component-1

Oil cooler component-1

Long hole shaped burring mold. Radius and straight length cross-section shape difference, minimized.

Material:A3003

Thickness:4.5mm

Oil cooler component-2

Oil cooler component-2

Large diameter grooved mold. We have changed our manufacturing process from conventional cutting and stamping to a new method of single stamping process.

Material:A3003

Thickness:4.5mm

Oil cooler component-3

Oil cooler component-3

Drawing diameterφ90~100, internal diameter tolerance of ±0.05 is achieved.

Material:SUS304

Thickness:0.8mm

Oil cooler component-4

Oil cooler component-4

Material:A3003

Thickness:4.5mm

EGR-C component

EGR-C component

Stainless steel sheet - precision bending, mold process.

Material:SUS430J1L

Thickness:0.8mm,1.0mm

Material:SUS444

Thickness:0.3mm

Pipe component

Pipe component

Integrally molded cylindrical shape and bottom plate

Material:BAW7-O

Thickness:1.6mm

* Made in Japan

Air-conditioner components

Air-conditioner control valve component

Material:SPCCThickness:3.2mm

Condenser component

Material:A3003

Automotive air conditioner-1

Material:A3003

Sensor component

Bind hole molding with stabilized dispersion.We have achieved a 25% cost reductions with our new method without using cutting process.

Heater core component

Irregular shape multi stage molded productMaterial:A3003

Thickness:undisclosed

* Developed in Japan (for future production)

Automotive air conditioner-2

Controlling slight warpage in product by stamping processMaterial:SPHC

Thickness:2.6mm,4.0mm

Air-conditioner component

Material:A5052Thickness:0.6mm

Air-conditioner control valve component

Air-conditioner control valve component

Material:SPCC

Thickness:3.2mm

Condenser component

Condenser component

Material:A3003

Automotive air conditioner-1

Automotive air conditioner-1

Material:A3003

Sensor component

Sensor component

Bind hole molding with stabilized dispersion.

We have achieved a 25% cost reductions with our new method without using cutting process.

Heater core component

Heater core component

Irregular shape multi stage molded product

Material:A3003

Thickness:undisclosed

* Developed in Japan (for future production)

Automotive air conditioner-2

Automotive air conditioner-2

Controlling slight warpage in product by stamping process

Material:SPHC

Thickness:2.6mm,4.0mm

Air-conditioner components

Air-conditioner components

Material:A5052

Thickness:0.6mm

Engine / Transmission components

Common rail component

Material:SPCCThickness:1.0mm

Valve lifter component

Material:SCM415Thickness:2.85mm

AT Shift component

Material:SPFH590Thickness:3.2mm

Power steering pump component

Material:SAPH400Thickness:3.2mm

Bike component

Minimal shear droop burring formationMaterial:SPCC

Thickness:2.0mm

Common rail component

Common rail component

Material:SPCC

Thickness:1.0mm

Valve lifter component

Valve lifter component

Material:SCM415

Thickness:2.85mm

AT Shift component

AT Shift component

Material:SPFH590

Thickness:3.2mm

Power steering pump component

Power steering pump component

Material:SAPH400

Thickness:3.2mm

Bike component

Bike component

Minimal shear droop burring formation

Material:SPCC

Thickness:2.0mm

Body / Suspension components

Caulking nut component

Material:Boron steel (N22CB)Thickness:8.0mm

Retractable power door mirror component

We have achieved a 25% cost reduction by eliminating the sintering process.Material:SPFH540

Thickness:3.5mm

Reclining damper component

Material:SPFH540Thickness:3.8mm

Suspension component

Material:SPFH590Thickness:3.2mm

Door component

Material:SAPH400Thickness:8.0mm

Slide door component

Material:SPH270Thickness:6.0mm

Drum brake component

Product hardness control using stamping processMaterial:SPH400

Thickness:6.0mm

Automobile seat component

Minimized shear droop and secured 80% clear cut surfaceMaterial:SPH440-OD

Thickness:2.9mm

Caulking nut component

Caulking nut component

Material:Boron steel (N22CB)

Thickness:8.0mm

Retractable power door mirror component

Retractable power door mirror component

We have achieved a 25% cost reduction by eliminating the sintering process.

Material:SPFH540

Thickness:3.5mm

Reclining damper component

Reclining damper component

Material:SPFH540

Thickness:3.8mm

Suspension component

Suspension component

Material:SPFH590

Thickness:3.2mm

Door component

Door component

Material:SAPH400

Thickness:8.0mm

Slide door component

Slide door component

Material:SPH270

Thickness:6.0mm

Drum brake component

Drum brake component

Product hardness control using stamping process

Material:SPH400

Thickness:6.0mm

Automobile seat component

Automobile seat component

Minimized shear droop and secured 80% clear cut surface

Material:SPH440-OD

Thickness:2.9mm